Great things in business are never done by one person. They’re done by a team of people.

-Steve Jobs

GENERAL DESCRIPTION

Steel pipes are coated with a corrosion prevention system, either at the factory or on the construction site. Alongside a simple application process, factors such as a long service life and, in particular, reliable protection against corrosion and mechanical loads are key.

The rehabilitation of coatings on complete pipelines or sections of pipeline takes place while the pipe is in operation, so the pipe does not have to be taken out of service, which is an exercise that can prove costly. Due to the risk of explosion, only cold-processed corrosion prevention systems can be used in these applications. To put the pipeline back into full operation quickly, the process for applying the product must be rapid and simple, like the ones offered by TAIL through its partners.

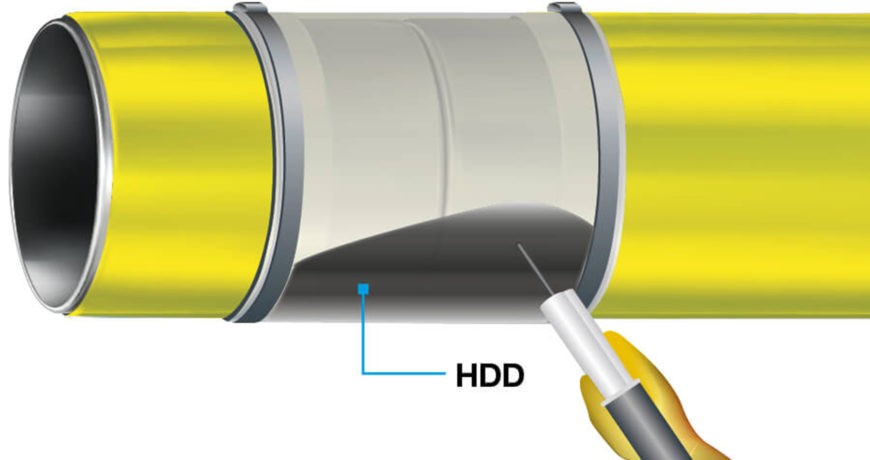

Alternatively, when the individual steel pipes are welded together to become pipelines, the coating that was applied in the factory must be partially removed.

Once the pipes have been fused together, a new coating is applied to the welded seam to protect them against corrosion and mechanical loads. The sensitive weld seam must be at least as well protected as the rest of the pipe – because a chain is only as strong as its weakest link.

In addition to a simple application process, a long-life, reliable corrosion protection solution and good resistance to mechanical loads are also important factors – and the maximum operating temperature must always be taken into account too. DENSO’s system solutions offer weld seam coatings for all kinds of processes, including cold or hot processing and spray and liquid coatings, e.g. for special applications.

Types

DENSOLEN (PE/Butyl Tapes)

The layers of the tape fuse together, due to the 3-ply structure, to create a protective hose that is fully sealed. Immediately after application, the pipeline can be operated at full load. Many millions of metres of DENSOLEN®-PE/butyl tapes successfully protect pipelines across the world.

DENSO-Cal

For almost a century, cold-processed DENSO® tapes have been used as corrosion prevention coating on pipelines at operating temperatures from -40°C to +110°C or -40°F to +230°F. With the invention of the petrolatum tape in 1927, DENSO set the quality standard for passive corrosion prevention.

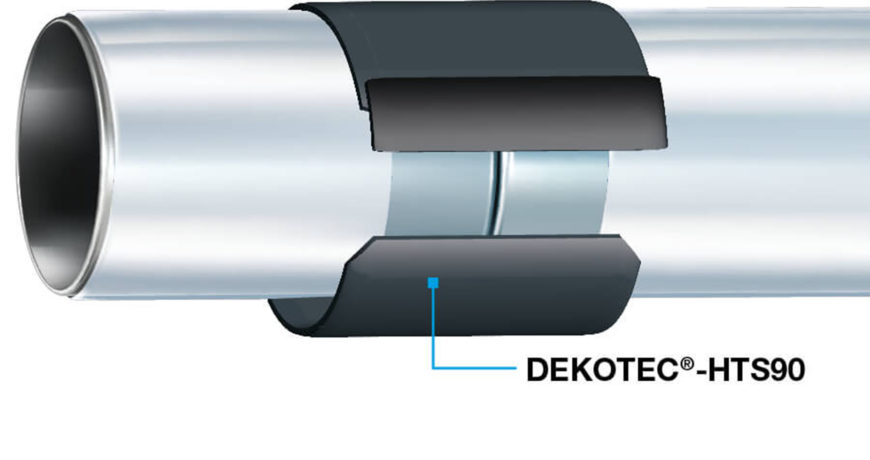

DEKOTEC-HTS/MTS

Our DEKOTEC® heat shrinkable sleeves are applied directly to the steel surface as a two-layer (without primer) or three-layer (including primer) corrosion prevention system. The systems are easy to apply without a time-consuming preheating process (DEKOTEC®-MTS) and are extremely resistant to operating temperatures ranging from -40°C to +90°C or -40°F to +194°F (DEKOTEC®-HTS).

CERTIFICATION

-

- DVGW

- OVGW

- SVGW-SSIGE

- Synergrid

- PCT

- Cerema

- KTH (Dr. Heim Institute)

- KIWA

- DIBt

- COPRO

- IFTA

- EOTA

- Polymer Institute

- Instyut Badawczy DrogiMostow